UNDERSTANDING RELOADING 2-, 3-, AND 4-DIES SETS

Tags:

by Heidi Lyn Rao

Avid shooters go through different stages in their shooting journey. Some shooters advance to competitive shooting, some explore different types of firearms to shoot, and some go the route of becoming a certified NRA Firearms Instructor. Yet, there are some very dedicated shooters who commit to all three! There is one shooting-related activity that most avid shooters end up doing, and that is reloading.

A great source for learning how to properly reload is to take an NRA Metallic Cartridge Reloading course or a Shotgun Shotshell Reloading Course. I have found that one of the first things an individual wants to know when they begin their journey reloading, is the difference between the different reloading dies and die sets. This includes the

difference between steel dies and carbide dies. It also includes explanation and clarification among 2-die sets, 3-die sets, and 4-die sets.

Steel Dies vs. Carbide Dies

Reloading die sets can come in two materials. Die sets can come in steel or carbide. Steel dies are cheaper in price than carbide dies because of the production costs. When using steel dies it is necessary to lube the cases when reloading. These dies are strong and are suitable for the average person who reloads at home. The press set-up is also easier with steel dies because the die can come into contact with the shell holder when the press is “cammed over”. The downside to steel dies is that they can wear out quicker than carbide dies. They are also not recommended for use in high production applications.

Carbide dies are more expensive than steel dies but last longer and are more durable. When using these dies, lubing the cases is not required when reloading straight wall or tapered pistol cases. Lube is still required when reloading bottle-necked cases and larger straight wall cartridges such as .45-70 Govt., .357 Rem Magnum, or .500 S&W Magnum. Carbide dies are better suited for high volume production.

The downside of carbide dies is that they are harder to set-up than steel dies, because the die should not come into contact with the shell holder. The die must be adjusted where it does not come into contact with the shell holder by performing small, incremental adjustments in the depth of the die. The carbide die can become damaged if it comes into contact with the shell holder. A cracked carbide ring can destroy the die to the point where it cannot be repaired.

In carbide dies, the majority of the die itself is steel. There is a carbide ring that is pressed into the opening at the bottom of the die. This makes it easy to tell a steel die from a carbide die. All you have to do is turn the dies over and look at the opening. If you see a light colored to a gray ring around the opening, you are seeing the carbide ring.

- Die Sets

2-die sets are usually used when reloading bottle-neck cartridge cases. This die set is the minimum required for reloading. The 2-die set includes a resizing die and a bullet seating die. The resizing die is usually a full-length resizing die. This die usually includes the de-capper for removing the primer. The second die, the bullet seating die, sets the bullet at the correct depth and includes a feature to secure it to the case, such as crimping.

The advantage of a 2-die set is that it works very well for firearms that move the cartridges from a magazine to the chamber such as semi-automatic, lever, and pump action rifles. This is because it ensures that the cartridge is resized to factory specifications to easily cycle through the action. The 2-die set is also easily mastered by beginner reloaders.

The disadvantage of the 2-die set is that it can limit the number of times that the brass can be reloaded. This is because this die set usually does not include a neck-sizing component. This weakens the neck and shoulder of the cartridge and can lead to the brass deforming. Another disadvantage is that it could lead to feeding and chambering issues in bolt action firearms. This is because most bolt action firearms are chambered to accept bottle-neck cartridges.

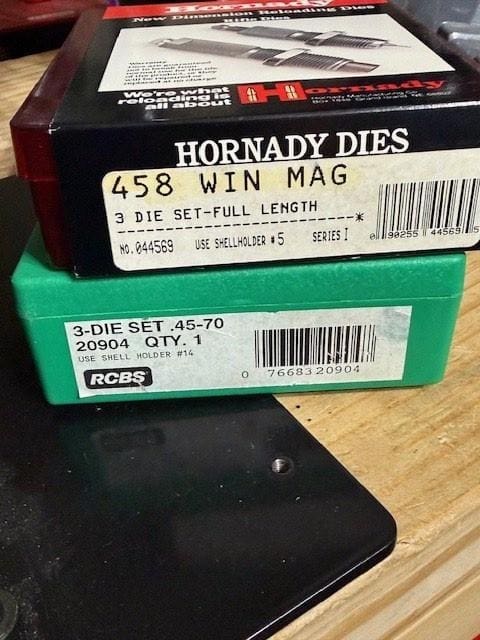

- Die Sets

3-die sets are usually used when reloading straight wall and bottle-necked cartridge cases. The 3-set dies include the full-length resizing die and the bullet seating die but also includes a re-sizing neck die or an expander die. The first two dies do the same thing as in the 2-die set. The third die does different things depending on the type of cartridge being reloaded.

If the die set is for a straight wall pistol cartridge such as a 9mm or .45 ACP or a revolver cartridge such as a .357 Rem or a .44 Rem, the third die expand the mouth or the case for easy bullet insertion. The expander dies “bell” the mouth so that the case does not “shave lead” when the bullet is pushed into the case.

If the die set is for a bottle-neck cartridge, this die re-sizes the neck. It also ensures that the shoulder is set back to specifications. If the reloaded cartridges are shot out of the original firearm, many experienced reloaders only resize the neck. This allows for the

smooth chambering of the cartridge while leaving the body of the case in its expanded state. By leaving the body in this state, it fits exactly to the chamber of the firearm it was shot out of.

The 3-die sets ensure smooth chambering of bottle-necked cartridges in bolt action rifles and for easy cycling of cartridges in semi-automatic pistols. These sets also are very easy to use in progressive presses when an individual is producing high-volume quantities of ammunition.

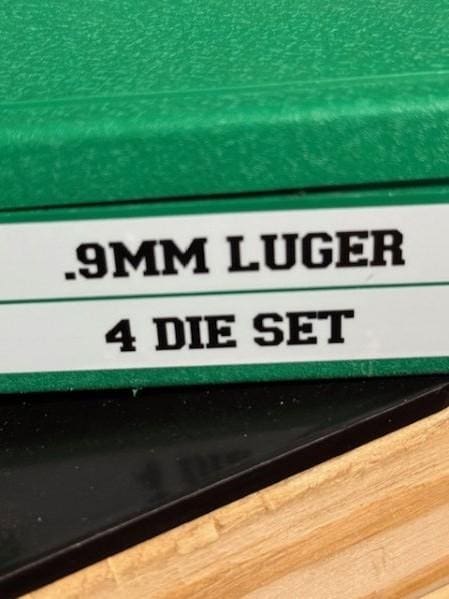

- Die Sets

4-die sets include all the dies in a 3-die set and additionally includes a dedicated enhanced die. Reloading 4-die sets are generally used when reloading cartridges for precision and accuracy, such as for competition shooting. A fourth die could include a dedicated factory crimp or a taper crimp die. The fourth die could also be a dedicated neck-sizing die, bushing die, body die, or a micrometer seating die. These dies have very precise uses.

Factory crimp dies use a collet-style crimp to ensure a very tight bullet hold without increasing the pressure of the cartridge.

Taper crimp dies for semi-automatic cartridges such as the 9mm, .45 ACP, or .40 S&W are used to prevent the bullet from being seated too deeply and these dies also help with feeding reliability.

Neck-sizing dies are used for only re-sizing the neck on bottle-necked cartridges.

Bushing dies are used by competitive shooters to adjust the neck tension holding the bullet.

Body dies are used by advanced cartridge reloaders who want to re-size the body of the cartridge while leaving the neck of the cartridge at its expanded state to be used in the original firearm that shot it.

Micrometer seating dies are used by competitive shooters for precise bullet depth adjustments.

Depending on the cartridge, reloading can be cost beneficial. The brass alone can account for up to 40% of the cost of factory ammunition. The question that I am most often asked, is “How many times can a case be reloaded?” The answer is “It depends on several factors including the quality of the brass, the powder charge used, and/or the skill of the reloader, just to name a few.” It is important to remember that the more the brass is resized or manipulated, the shorter the lifespan of that reloaded cartridge.